Additive Manufacturing

PRECISION 3D PRINTED PARTS, ECONOMICAL AND FAST

Our fleet of industrial composite 3D printers revolutionise our manufacturing operations and are capable of capable of printing continuous fibre reinforced parts that are capable of replacing machined aluminium. Using leading 3D print technology and additive manufacturing allows us to produce quality prototypes and then build parts quickly with reliable, repeatable results. Reap the benefits through massive time and money savings on parts making your entire operation more competitive and efficient.

Contact UsOur 3D-printers

Markforged FX20

Our sleek FX20 is an industrial composite 3D printer. Combining reliability and performance with its turbo mode, printing is incredibly fast and precise. This versatile large format printer can build everything from factory tooling and fixtures to flight-ready production parts.

PRODUCT MATERIALS

Markforged X7 CFR

Our Markforged X7 CFR is an industrial carbon fibre 3D printer that builds continuous fibre into accurate, repeatable parts. It is optimised to resist wear and can maintain print quality over thousands of hours.

PRODUCT MATERIALS

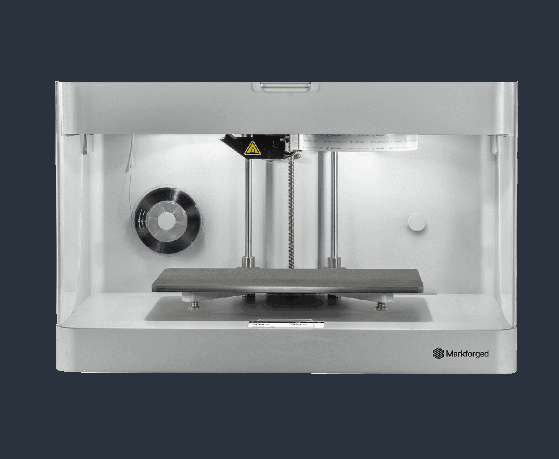

Mark II

Our carbon fibre composite 3D desktop printer has a reinforcement system that enables printing of continuous fibre into parts that can be as strong as machined aluminium. It delivers high accuracy and repeatability.

PRODUCT MATERIALS

Metal X System

Our Metal X 3D Printer fabricates durable metal parts, an intuitive 3D printer capable of printing complex closed cell infill (triangular) or solid metal parts. This printer builds with metal powder bound in a plastic matrix which eliminates many safety risks associated with the use of loose powder in the manufacturing process.

PRODUCT MATERIALS